An experiment to see the inner effect of hardening

Sometimes we are told by polishers that a newly produced blade is harder

than old blade on their hamon.

We can see that old blades tend to have milder hamon lines than newly produced

blades'. On the other hand, there are some very healthy blade from 13th

century that have still tight hamon lines.

Usually old blade has been more ground than new blade. If a hamon becomes

milder inside of the blade, it would be changed by grinding. We already

have some happenings that suggest so.

(=> Naohiro tanto) (=> Episodes by Kokaji, grinding Iai master's blade) (=> Tanto of worn out)

Then we planed an experiment to see the inner effect of hardening. That

is to grind a blade at one side and study the appearance on each surface.

The blade for this experiment should have the same quality

steel on both sides, for example, made with "KOBUSE" steel construction and has a small amount of inner steel. Because

it would be ground much at one side and the inner steel should not appear

on the hamon. Then we will be able to see the difference of hamon between

on the intact surface and on the ground surface.

However this mission means destroying blade. It might be a terrible work

in a sense. We never want to destroy blades anyhow. Therefore we have been

waiting for a suitable blade coming from our smith's forge.

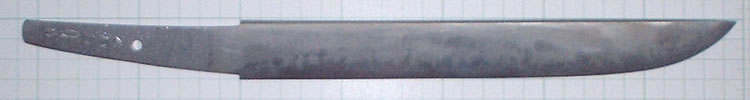

Fortunately, or unfortunately, a suitable tanto has appeared. It was made

by the smith but he was not satisfied with the result. Then he accepted

to grind it for this experiment.

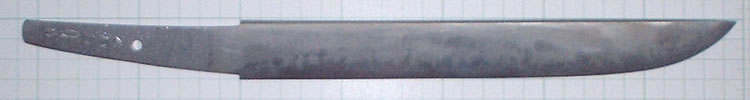

The tanto has been hardened and done rough polishing to see the result

of the hardening work. It has very active choji hamon pattern on both sides.

Blade length 24.5cm, curvature 1mm, width at the base 3.1cm,

weight 310g

Thickness at the base on the back 8.5mm

Thickness of cutting edge 2mm,

It is going to be ground on the obverse side.

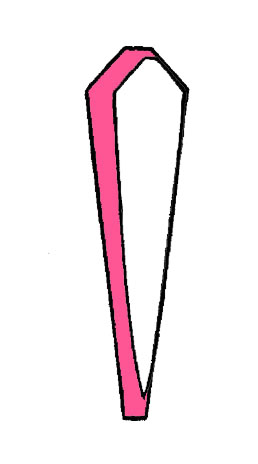

The tanto has been ground much on the obverse side. The thickness of the back was removed with 1.5mm. The weight was removed with 55g. The width is not changed.

Weight 255g

Thickness at the base on the back 7mm

The cutting edge still has a small amount of thickness.

The blade has bent to the ground side. Because the pressure of the hardened

area was decreased by grinding.

Then the blade is going to be straighten and shaped.

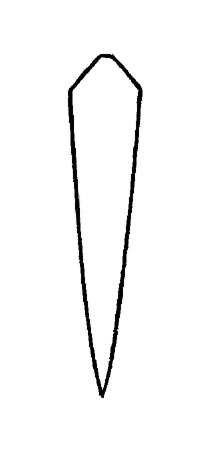

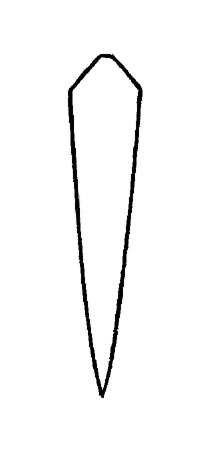

The blade has been shaped.

Weight 230g

Thickness at the base 6.5mm

Width at the base 3.0cm

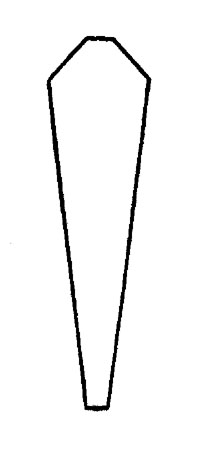

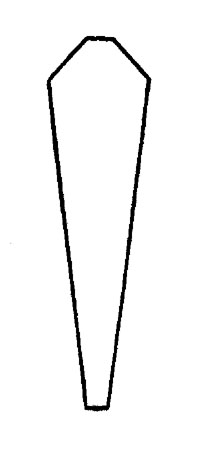

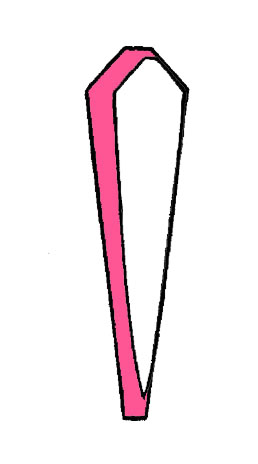

At the drawings bellow, the left is just after hardening, the center illustrates

the part that ground off, the right is the completion of shape.

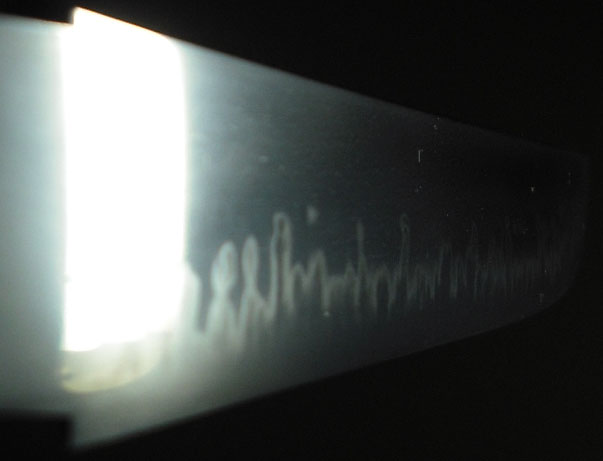

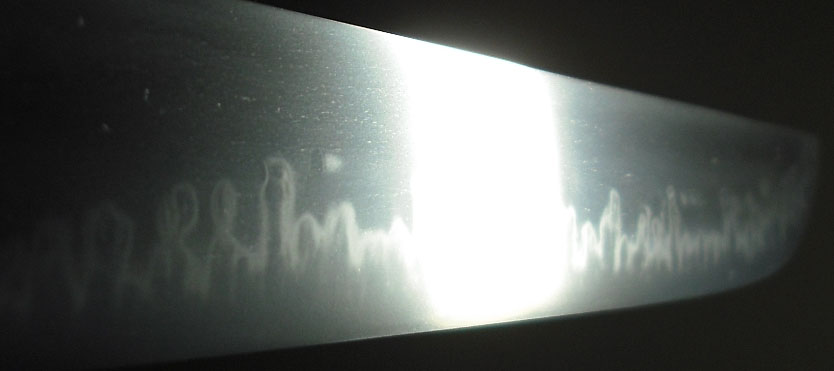

Even in this stage, we can see that the wild hamon pattern on the obverse

side has changed to calm.

Before

After

Now, it is going to a polishing stage.

Hazuya work

Polished up. Let's study the difference between the obverse side and the

reverse side.

Home > Information, Smithing > Inner effect of hardening