Preface

We have several customers who ask us that they want to make Japanese blade by themselves. Most of them make Japanese style blade using modern steels. But some of them are trying to take the traditional method using the traditional material.

The traditional steel to make blade is called "Tamahagane". (=> Tamahagane and Oroshigane)

The way of forging Tamahagane is difficult to learn by amateur's self studying. We think most of such challenges must conclude as just wasting the steel. If you really want to make traditional Japanese blade, you should be an apprentice in some sword smith who make real traditional Japanese blades.

But, not all such customers can become apprentices, and some of them still want to challenge eagerly. Then our smith introduces one of the way to forge Tamahagane. This system is also taken by apprentices in his forge. He hopes this introduction can help to save the respectable steel.

Preparing Tamahagane or Oroshigane.

(Tamahagane and Oroshigane, they are almost same in the meaning of their quality. So I will use the word "Tamahagane" to mean also Oroshigane, in this page.)

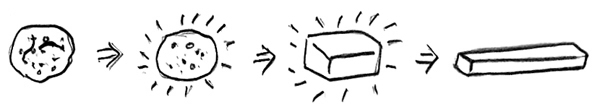

Several pieces of Tamahagane are prepared.

They are heated and pounded to be flat plates with the thickness 6mm to 10mm, then heated again and put into water. Some of the steels may be so brittle that difficult to be flatten occurring many cracks. Such steels are too hard or including much slag. Broken off steels go back to the Oroshigane stage again.

Hardened flat steel plates are appeared.

Break the flat plates to small pieces, and study the break out surfaces. It means researching the steel quality.

Classify the small pieces into several qualities.

For example;

A, soft = difficult to break

B, medium hard = a little hard to break

C, hard and dense = easy to break and the break out surfaces are dense = good for edge

D, hard and rough = easy to break and the break out surfaces are rough

E, too hard = brittle and occurring many cracks

Small pieces of Tamahagane are classified into several qualities.

(If you are quite starter, you can classify them just into two kinds, hard pieces and soft pieces. Breakable pieces are hard, and the other pieces are soft. You can make a blade with the two-block steel construction. Only small amount of hard steel is necessary, since it is used only for edge.)

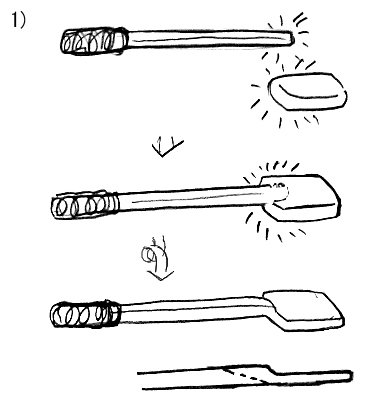

Making a handle for fold and welding work.

The part wrapped with cloths is gripped by the smith to take the blade steel in the fire. This part can be made of modern steel. The other end is connected with the blade steel. So the part must be made of Tamahagane.

Prepare a bar of modern steel. It becomes a part to grip.

Pick up a piece of Tamahagane. Heat it to the welding temperature and pound it to make a bar of Tamahagane. It becomes a part where the blade steel is connected.

Heat the end of each bars to the welding temperature and weld them together to make a long bar what is jointed with Tamahagane and modern steel. This does not become a blade, it is a tool for fold'n welding work.

Please notice that, the modern steel of the handle never runs into the blade.

Whenever I heat the steel to the welding temperature, I coat the steel with black ash of rice grass. It saves the steel against burned by fire.

Planning what blade you will make.

There are several kinds of blade styles, and several kinds of steel construction. (=> styles, => steel construction)

In this lesson, I will go on the way to make a hira-zukuri tanto blade by the two block steel construction. It is simple and useful for study and practice. Such a blade is constructed with two kinds of steels. Those make sharp cutting edge and tough body.

Preparing the small pieces of Tamahagane for each steels (edge steel and body steel).

For the cutting edge steel, prepare the hard and dense small pieces, 1kg to 2kg.

For the body steel, prepare the medium hard small pieces, or mix with soft, medium hard and too hard ones. Anyhow the total hardness should be medium. The amount is also 1kg to 2kg in total.

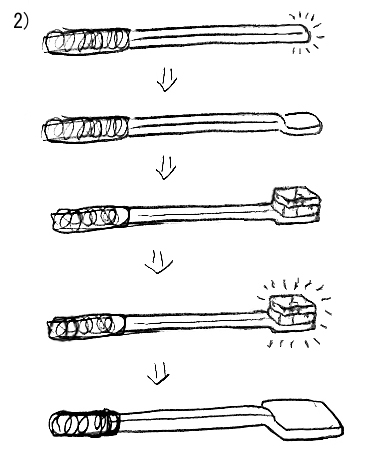

Making the paddle to put small pieces of Tamahagane on it.

I introduce two ways of it. You can choose either. Anyway, the paddle should be the same quality to the small pieces what put on it.

1)

Pick a piece of Tamahagane. Heat it to the welding temperature and pound it to make a square block.

Heat the end of the handle and the square block to the welding temperature and weld them together. Pound the square block part to make a flat base.

2)

Heat the end of the handle and pound the part to make a small flat base. Put small steel pieces on the base. Heat it to the welding temperature and pound it to make a flat square base.

The fold and welding work

The purpose of this work is making an even and dense quality steel.

Making the steel for edge

Hard and dense small pieces of tamahagane are selected. It is purposed to get sharp edge.

Put the small pieces of Tamahagane on the base making the outline square. The base must be made from the same quality of tamahagane to the small pieces what put on it.

Heat it to welding temperature and pound it. The gathering of small pieces becomes one square block. Then cut it and fold. Then heat and weld again. It will repeat 10 times to 15times.

When I heat the steel in this work, I coat it with black ash of rice grass and clay water.

When the fold'n welding work has finished, the steel must become hard and dense. The steel is cut off from the handle.

Making the steel for body

This time, the goal is getting a tough steel. So the selected small pieces of tamahagane are softer than the edge steel in total. You can take a mix forging with soft steel pieces and too-hard steel pieces.

The fold'n welding work is the same to the work of making edge steel.

When the work has finished, the steel is not cut off from the handle.

Constructing the steel for blade

Now, the two steels, the cutting edge and the body, are prepared.

The cutting edge steel is shaped to put on the body steel. The body steel is still being with handle.

Weld them to one steel for the tanto blade.

Drawing out the steel to the length of the blade.

The length of the steel should be a little shorter than the length of the planed blade. Because the blade will be extended on the next stage. You must work carefuly on this stage to get a proper shape.

Shaping the blade by hammering.

Shape the blade with shorter curvature than that you planed, because some amount of curvature can occur by the hardening work. Of course, careful work is necessary.

Shaping the blade with plane and file.

An exact work is necessary.

Hardening the blade by the heat treatment. (=> actual examples of YAKI-IRE)

You can put the clay mixture with any designing. It may make some effect to the pattern of hamon. Anyhow the hamon is not made by the clay. The steel quality and the hardening work makes hamon.

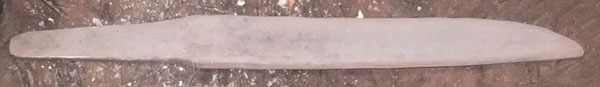

Just after the quenching work

Shaping the blade by the stones.

Probably the blade is bending by the hardening work. You should heat the blade a little bit, and straighten it with hammer. Then shape the blade with several stones, from the rough stone to the fine stone. Then finish the tang and drill a hole on it.

Polishing the blade.

You should polish the blade by your self. During the polishing work, you can study the results on the blade. If you ask the work to professional polisher, a simple Hazuya finish or Sashikomi finish is necessary to study the blade quality. Any aesthetic finish is just a trouble to see the real face of the blade.

If the forging work and the hardening work are proper, the hamon would be bright and clear, not only the hamon line but also the hardened area. Any hamon pattern has small meaning to blade quality.

You will be able to study the difference of steel particles between the cutting edge steel and the body steel.

(=> Tanto Naohiro by the two block steel construction)

Another sample

------------------------------

If you want to try tamahagane, please email us. We can help you to purchase tamahagane from NBTHK. (=> Others1)