Then the plain wood scabbard is brought to the lacquer worker. He glues the horn fittings and paints the scabbard with urushi lacquer.

After one month, the urushi lacquered scabbard is brought back.

A pair of shitodome are put on the kurikata.

Now, the wood handle and the scabbard are brought to the handle worker.

The scabbard is necessary to fix the shape of the handle. The whole shape of the mount (scabbard and handle) must be well matched.

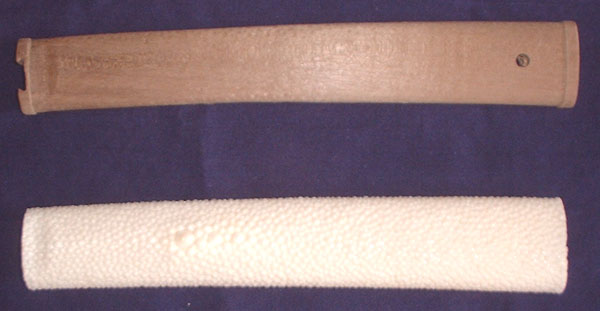

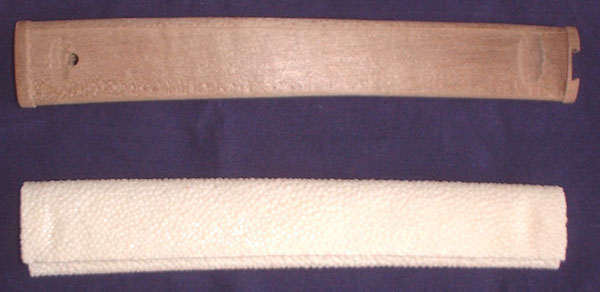

The ray skin is prepared.

(And the menuki must be prepared in advance of the cord wrapping work.)

The middle part of ray skin is cut out for the size that accord with the handle.

He shaves the handle wood considering the thickness of the ray skin. A ray skin doesn't have even thickness, and it becomes soft by being wet.

He temporarily wraps the wet ray onto the handle. After it becomes dry, he checks the shape and shaves the wood to get proper shape. He has to take temporary wrapping again and again until getting the proper shape.

The shape is done. In this case, the style of ray skin wrapped is one round and half. (=> Style of Ray skin Wrapping)

The depressions near the kashira are to settle the knots of cord. Another depression near the fuchi is to make the top of the crossing cords down. It keeps the top of the cord away from the kozuka drawing.

He glues the ray skin onto the handle wood. He then drills the hole for the pin.

(In some cases, the handle in this stage is brought to the lacquer worker again, to coat the ray skin with urushi. The work makes the handle strong and water proof. It takes some weeks, and then it is brought back to the handle worker again.)

The menuki and cord color is selected.

He glues the kashira, and starts wrapping the ray-skinned handle with the silk cord.

About the menuki direction.

On the case of the menuki that has a running animal design, it has to run towards the kissaki. Opposite direction is not good, as it is called "coward menuki". Because it suggests escaping the blade.

The handle is completed.

All parts of mount meet together. They are worked by different craftsmen. This means we fix them and tune them up completely.

If our directions to the each craftsmen were not proper, we would find serious problem at this step. But everything is OK.

Put the cord onto the scabbard. Then, the wakizashi koshirae is completed. It takes about 4 or 5 months from the planing to the completion.

Then we should find a suitable kozuka for this wakizashi.

Finally we have found a kozuka that the motif accords with other fittings.

A blade for it is prepared, and the tang of it is fixed with the kozuka by pine resin.

Anyhow, for producing mounts, a good director is necessary. A knowledgeable person should keep watching every process of the works keeping in mind a vision of the completed mount.

A good mount is not promised even if every craftsman is good. To arrange a craftsmen's network is very important for producing Koshirae.