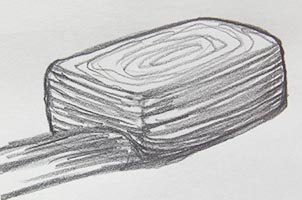

In the next pictures, the left is an actual steel block in the work of fold'n welding, and the right is a rough drawing what the layers grow in it.

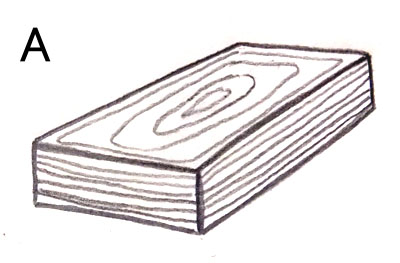

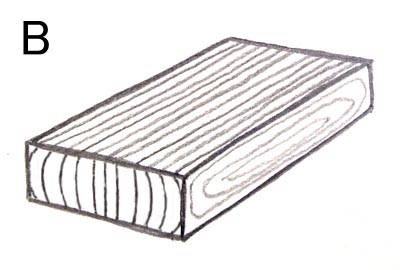

The next two drawings are samples of folded steel showing steel layers. They are typical two ways to shape a thick plate.

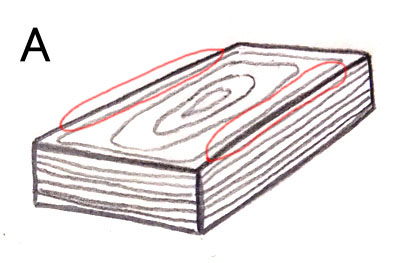

A has a wood grain layer pattern on the surfaces, and a straight pattern on the sides. It was pounded in simple way to make a flat plate from a block.

B has a straight layer pattern on the surfaces, and a wood grain pattern on the side. The forged out steel block was turned 90 degrees, and then pounded to a flat plate.

Even on the surface of steel A, a straight layer pattern can appear at the area near the edge.

The layer patterns are not so simple on actual steels, but please remember those as a theory.

Now, let's study steel layers.

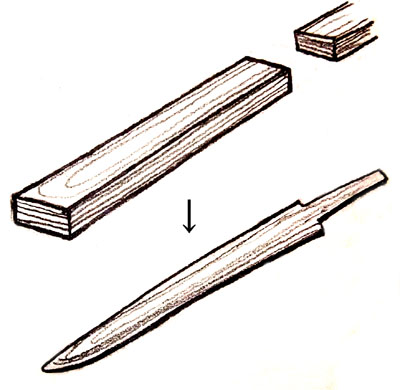

1, Kogatana

Blade length 13.5cm

The steel layer is type A. It is fold'n welded 12 times. The steel is drawn out and chopped, then shaped with hammer to the kogatana blade. Therefore the layer near the cutting edge must be a straight pattern.

The appearance near the edge does not look a straight pattern. It looks a small wood grain, but it is not the layer pattern. It is an activity of steel particles in hamon area. The area from the hamon to the back also has a small wood grain made of steel particles.

The layer pattern sinks under the activity of steel particles. Studying the hamon around the tip, the kinsuji (an appearance of hamon particles) suggests the layer that is a flowing pattern.

2, Another sample. It is three times folding. (=> K-un4)

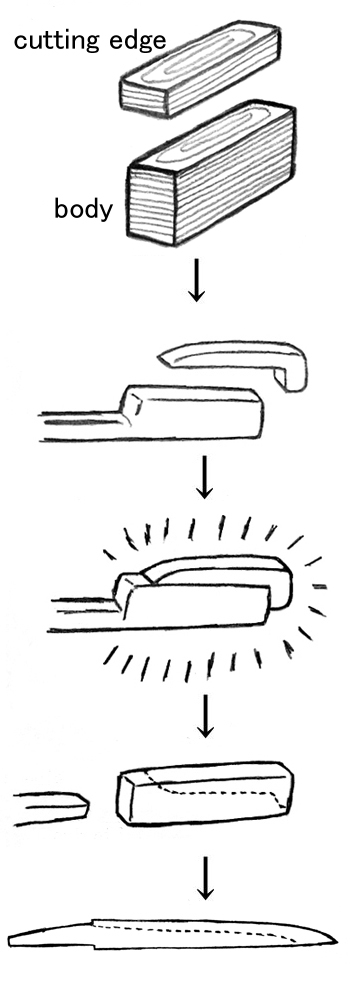

3, Tanto of the two-block construction

Blade length 24.5cm

The blade is constructed with two different steels, those are the cutting edge steel and the body steel. The cutting edge steel is type A, hard and dense steel pieces are selected, and fold'n welded 15 times. The body steel is type B, mild steel pieces and too hard (brittle) steel pieces are selected, mixed, and fold'n welded 11 times. The cutting edge steel is hard and dense to get a sharp edge, while the body is mild and tough.

4, Tanto of the sandwich style construction

Blade length 20.2cm

5, Samples of Kobuse style construction (=> Tachi and wakizashi)

6, Conclusion

The grain on the blade surface is not only by the layer pattern. The activity of steel particle also is effective to make grain in the steel.