Forging the blade

This time he tries a blade with straight layer pattern. So the steel construction is the sandwich style (three layer).

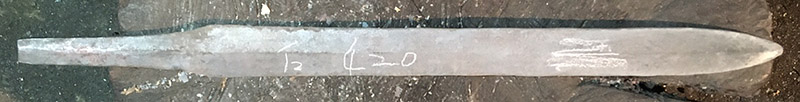

New sword 1B

Ken blade with straight layer pattern (Ken blade B)

Forging the blade

This time he tries a blade with straight layer pattern. So the steel construction is the sandwich style (three layer).

Fold'n welding work for the outer steel - Rough formed steel pieces are

picked up. Each of the pieces are formed with uneven quality in itself.

Some parts are hard, and other parts are soft. Some parts are rough and

other parts are dense. They are rather soft comparing with the core (edge)

steel. The steel pieces are welded to one block, and folded 8 times. Then,

it is turned 90 degrees to show the steel layer on the surface. And it

is cut into two pieces those become the both sides of the blade.

Making the core steel

It is on the half way of fold'n welding work. It has been folded 5 times,

and will be folded more.

The steel is covered with rice straw ash, and put into the forge again

to get the welding temperature.

The core steel is forged out after 13 times folding. It becomes the edge

of the blade. And this steel block is cut in two. One is for this ken blade,

and the other is the ken blade A. So, ken blade A and B are sisters in

the meaning of the core steel. =>New sword 1A

And then, the steels, core steel and two pieces of outer steel, are welded

together to one steel block.

Shaped by hammer work

The the blade is shaped by the plane and files. Then, it is a time to harden

the blade.

Heating and quenching work