process of the polishing

work ( under construction,

please wait for photos )

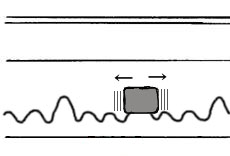

The restoring work is roughly divided two steps.

The first is shaping, next is polishing.

These two steps are very different on their action.

And the shaping is the most important for the blade, and most difficult

in the polishing work.

(=> shaping)

1) shaping

To restore the blade we shape it with stones.

We start with a rough stone, and step up toward finer

one to make the shape finer.

Normally we use some kinds of stones, from rough to fine,

Arato, Binsui, Kaisei, Chu-Nagura, Koma-Nagura, and Uchigumori.

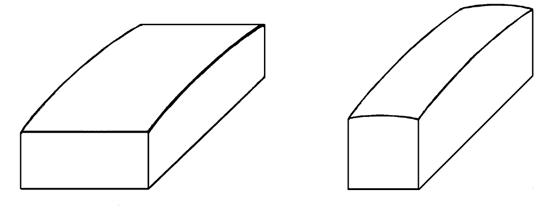

For this work, the shape of the stone is very important.

Wide stone is good for the flat surface (shinogi-ji) and the cutting surface.

Narrow one is good for the back surface.

Stones, there are two kinds, natural stone and artificial

one. Each kind has good point.

preparation

Before starting the shaping work, we have to study the

blade exactly to make a plan how shape it up.

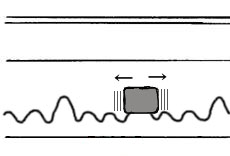

And straighten the blade with wood vice.

To make it exactly is very important to get good shape.

one example

of the work.

one example

of the work.

ARATO stone

The most rough stone.

We use it only for fresh borne blade or deep rusted one, to make a proper

shape.

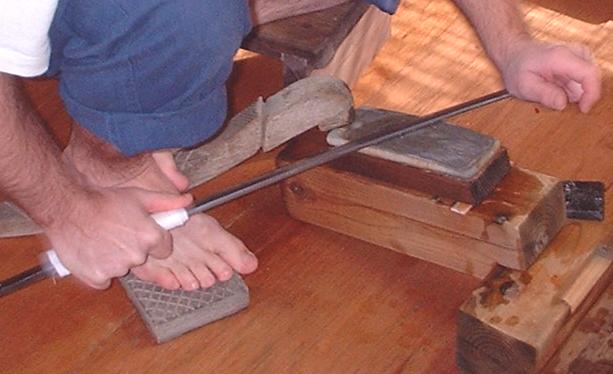

Hold the blade with right angle to the stone, and push

the arms forward.

For the flat surface (shinogi-ji), a little slant angle is not so bad.

For the back surface, hold the blade 45 degrees to the

stone, and push forward.

The work is same to the next step BINSUI.

This step is the most important for the shaping.

The system is very simple but it is the most difficult

in all steps of shaping.

Never grind too much steel.

We have to get the perfect shape with the least grinding.

( work for the cutting surface with an artificial ARATO

stone: carborundum#180 )

( work for kissaki )

( work for the back surface )

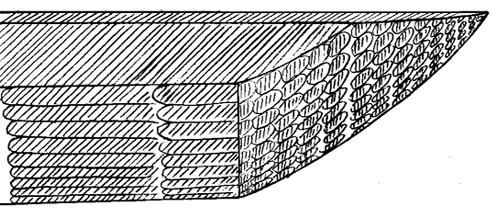

( the trace of the grinding work with ARATO )

( the cutting

surface )

( the cutting

surface )

( kissaki )

( the back surface )

BINSUI stone

Most of blades are started with this stone.

To remove rust and make a proper shape.

Be careful to save the meat on the cutting surface.

( work with a natural BINSUI stone )

( grinding

the stone surface often with another stone to keep its surface even )

( grinding

the stone surface often with another stone to keep its surface even )

KAISEI stone

To make the shape finer.

Hold the blade with 45 degrees to the stone, and push

the arms forward.

But the working system for kissaki never change with

any stones.

( work with an artificial KAISEI stone )

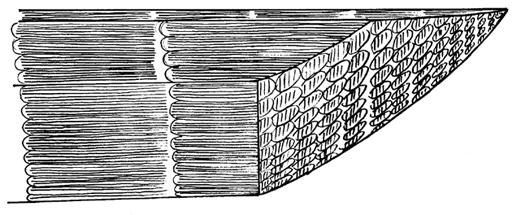

( the trace with KAISEI )

CHU-NAGURA stone

To make the shape finer.

From this step we never use artificial stones.

( In some case artificial stones are easy to be used

by hobby polishers. )

Hold the blade 45 degrees to the stone, and move the

blade along the blade's length.

The work looks like pushing the blade toward the left

hand.

The trace should be parallel to the length or a little

slant.

( the trace with CHU-NAGURA )

KOMA-NAGURA stone

To make the shape finer.

This stone is a little finer and harder than CHU-NAGURA

stone.

The work is same to CHU-NAGURA step.

But the trace has to be very parallel to the length.

UCHIGUMORI stone

To complete the shape and to make the character of the

blade come up.

Hold the blade the same way as in the previous step.

But the working direction is opposite.

It is pulling the blade carefully towards your right

hand.

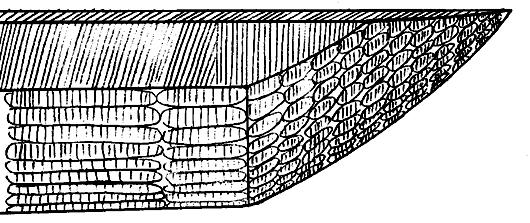

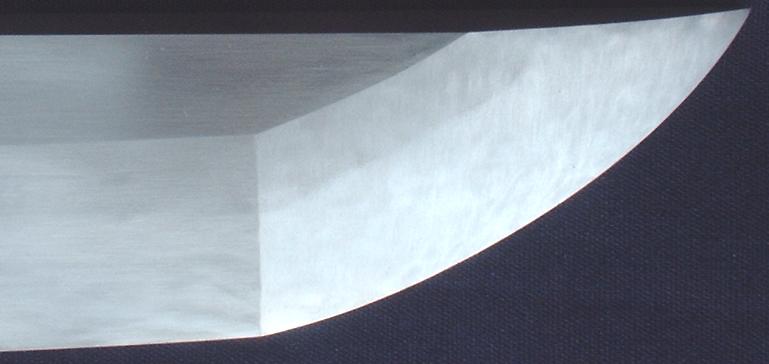

Then every surface is completely shaped, and the characters

come up. (hamon, layer pattern and etc.)

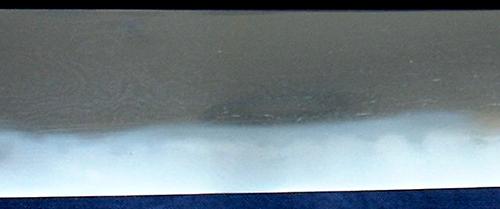

Next is one example of uchigumori result.

But it is not very good, because the layer pattern is

brought up too hard.

Such working style is a little rough for the steel.

The layer is dug by hard rubbing against the stone.

And the steel surface is not fine.

More tender work should be given to the steel.

2) polishing

To study the quality of the blade we make the surfaces

clear. Then we can see the details easily.

In the polishing work, there are two kinds of finishing

style.

One is the classical polishing style (SASHIKOMI).

The other is the modern polishing style (HADORI). (=> polishing)

The big different between them is in the step of NUGUI.

preparation

Before starting the polishing work, we have to make the

stuff for the work, HAZUYA, JIZUYA and NUGUI.

Good preparation is very important for smooth work.

making hazuya and jizuya

Hazuya is made from uchigumori stone. Jizuya is from

narutaki stone.

Both stones are similar kinds of finest stone in Japan.

Narutaki is a little harder than Uchigumori.

The fineness of texture and the hardness is very important

to select them.

Slice the stone with chisel and hammer.

slices

of uchigumori stone.

slices

of uchigumori stone.

Grind them to get flat surface and the thickness as thin

as paper.

grinding

narutaki stone.

grinding

narutaki stone.

hazuya,

the rectangle one is credit card size.

hazuya,

the rectangle one is credit card size.

various

qualities of jizuya, they become harder toward the right.

various

qualities of jizuya, they become harder toward the right.

Fix them on the paper with lacquer. The paper should

be thin and strong.

Cut and shape them to proper size.

Grind them again to the proper thickness to use.

The hazuya for NARUME work is larger size and the best

quality.

making nugui powder

Nugui is very fine powder mixed with oil.

Each polishers have their own powder making system and

material.

One of them is grind the material completely with mortar

to the finest powder.

Examples of the materials are, narutaki stone, tsushima

stone, iron ore, oxidized iron, and other things.

polishing migaki needles

There are some kind of needles with different shapes

for blades' surfaces.

Polish them up completely to get mirror surface on its

own.

The finish of needle surface moves to blade surface.

HAZUYA

HAZUYA is a very thin Uchigumori stone fixed on the paper.

Polish the blade surface with HAZUYA on the thumb completely,

especially in the hamon.

Then the surface becomes clean. And all the tempering

effects come to be seen.

JIZUYA

JIZUYA is a very thin NARUTAKI stone.

Some of them are fixed with paper, and some are not.

Choice is case by case.

And select suitable quality jizuya for the steel quality.

Polish the blade surface with JIZUYA completely except

the hamon area.

The steel becomes clear and the steel particles come

up.

NUGUI

NUGUI is a very fine stone powder mixed with oil.

Polish the whole surface of the blade with it using cotton

ball.

In this step, the work is very different between the

classical style and the modern style.

The nugui work in the classical style is the final cleaning

for the blade surface.

The work in the modern style is to make up a good contrast

for an attractive view.

On the classical style, natural stones can be used for

NUGUI.

There are various kinds of stone for it, for example,

NARUTAKI, NAGURA, TSUSHIMA, iron ore.

The surface becomes clean and the hamon comes up.

On the modern style, polishers have

their own special material and oil for nugui.

It is far harder than the classical style's to make a

black shining surface on the blade.

The work effects whole surface of the blade even on the

hamon.

So the hamon is masked by this hard effective polishing.

Then the hamon area has to be polished again with hazuya.

Polisher uses hazuya carefully by their thumb to make

a white pattern along the hamon.

This work is called "HADORI".

So this polishing style is called " HADORI style".

Good hadori work makes good contrast between the white

pattern and the rest black shining area.

On this work polishers are thinking to get an attractive

view.

So the pattern of white area is quite different by each

polisher's sense, even if the hamon would be the same.

And the real hamon can be seen in the white pattern when you use good lighting.

(=> HAMON)

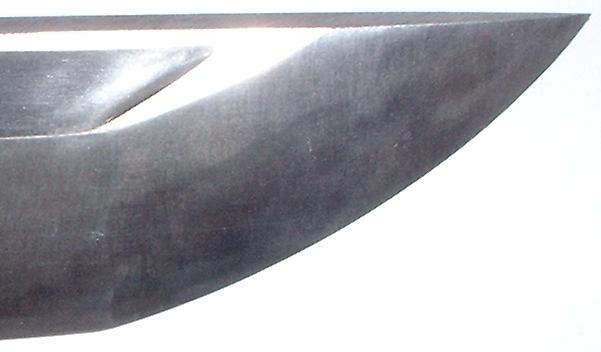

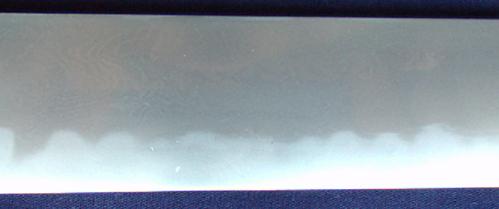

The nugui

and hadori on the modern style.

The nugui

and hadori on the modern style.

The same

part of the above blade by the classical style nugui.

The same

part of the above blade by the classical style nugui.

One more example of steel by classical style polishing.

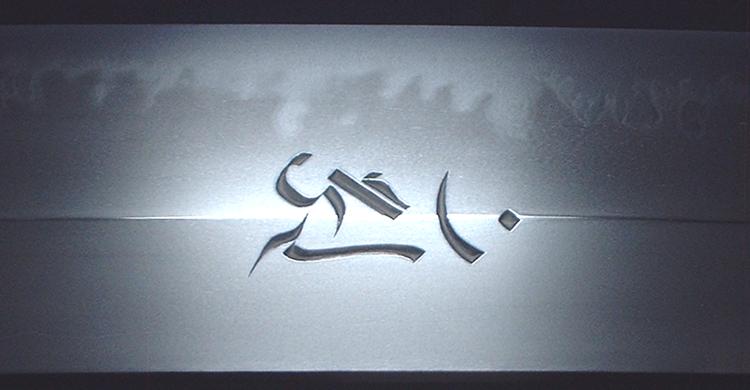

The hamon

of the same part of above blade.

The hamon

of the same part of above blade.

Be careful, some polishers use acids or chemical treatment on polishing

process to trick the view.

They emphasize hamon pattern and layer pattern, and its

view is indecent and unnatural.

However skilful it is, they never lift the blade quality

up, only damage the steel.

Such work is done for purpose to deceive beginners.

It is very bad for serious sword lovers.

Good polishing never use any acid.

MIGAKI

Rubbing Shinogiji and the back surface with a steel needle

to get mirror finish.

The

tools for migaki work, from the bottom, horn powder, needles, needle polishing

table and wax ball.

The

tools for migaki work, from the bottom, horn powder, needles, needle polishing

table and wax ball.

Various kinds of needles as their shapes and materials.

Various kinds of needles as their shapes and materials.

Remove fat on the surface completely. We use horn powder

wetting it.

Put wax to get smooth running of needle. We use IBOTA

wax putting like uchiko powder.

In the modern style polishing, a mirror finished shinogiji

is very common.

But on the classical style, the result of migaki should

be mild.

Some old classical style polishings have no migaki effect.

Such a blade has same view on the cutting surface and

on the shinogiji, and is good for study the blade.

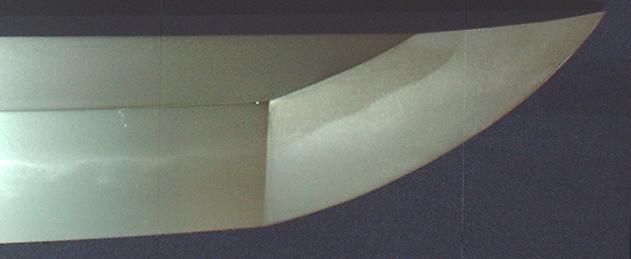

Befor Migaki work.

After Migaki work.

NARUME

To polish the kissaki with the best quality HAZUYA to

distinguish it from the other part of the blade.

Home > Information, Polishing > Polishing process

You can purchase any kinds of stones for blade polishing

at this shop.

NAMIKAWA HEIBEI CO. LTD.

e-mail info@namikawa-ltd.co.jp

postal address: 1-13-4 MIDORIGAOKA, MEGURO-KU,

TOKYO, 152-0034 JAPAN

telephone: 81-3-3718-4835

fax: 81-3-3718-4900

URL http://www.namikawa-ltd.co.jp