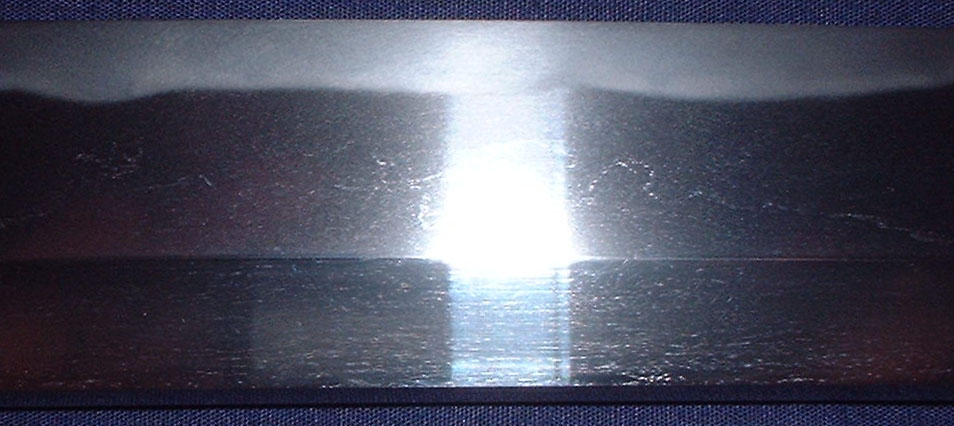

An example of the modern style polishing

"Hojoji Yoshitsugu"

Hadori

Hanon

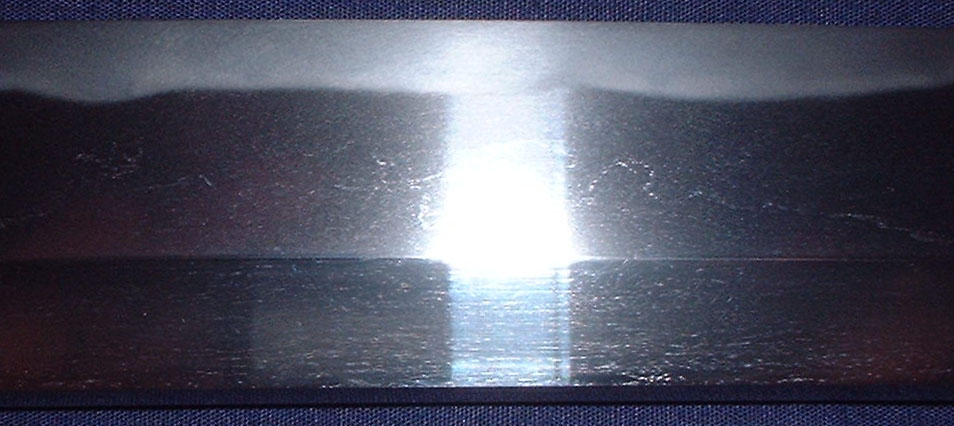

An example of the modern style polishing

"Hojoji Yoshitsugu"

Hadori

Hanon

One more example of the modern style polishing.

Hadori

"Is this hamon pattern NOTARE (wave)?" "No, it is not a wavy hamon. It is choji. But the hadori is wavy pattern."

Hamon

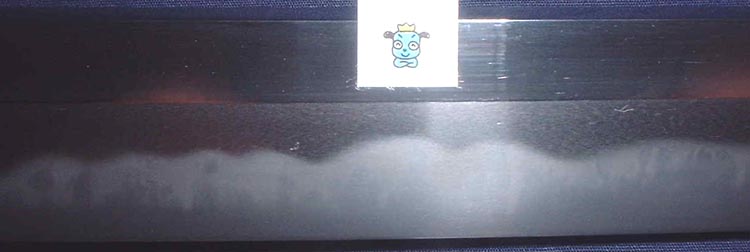

The classical style polishing (Sashikomi style polishing)

It leaves the color of the steel more natural. The blade looks dimmer than

one polished in the modern style, but when you look at the blade under

a proper light, you can see the true color of the steel and everything

comes up very honestly. In other words, the classical style shows

more the true nature of the blade , its glories and its flaws. The integrity

of this style of polish is a necessity for truly studying the blade.

This type of work can only be done with natural stones.

An example of the classical style polishing

"Tadamitsu"

This blade has a fine steel and very bright hamon line. All the characteristics

are brought out in a very natural way.

One more example of the classical polishing style.

Another example of the classical style polishing

Tanto, no-signature, hitatsura hamon

This blade has a nice Hitatsura pattern hamon. But the temper line (hamon

particle band) is not very bright. This dim hamon means a little lower

edge holding than the bright one. On the other hand, dim hamon suggests

tough edge, while bright one is sharp but tends to be brittle. Probably

this blade is re-heated a little longer after the quenching, preferring

a tough edge than sharp one. Such a dim hamon is often found on the blades

in Koto period.

In the classical style polishing, the hamon is not enhanced so we can see

its' true color. It is this clarity of polish in the classical style that

allows us to determine the hardness of the edge.

=> Episodes by Kokaji, an interesting story of polishing styles

=> Process of the polishing work

=> Several styles of blade polishing

The modern age has seen the rise of "Acid" polishing. This form

of polishing uses various acidic compounds to artificially expose the blade

structures. It is used in both Modern and Classical Style finishing and

I cannot stress how deplorable I find this technique.

=> Acid polishing.

NAGASHI

On shinogi-zukuri blades without grooves, the shinogi-ji is rubbed with

needle to get a mirror finish. The rubbing work ends at the lower part

of mune-machi. Sometimes we find lines below there. We call it "NAGASHI".

The polisher extends the rubbing work toward the tang as several lines

to show his skill. Straight and parallel lines suggests his good skill.

Nagashi is put also on the back of kissaki.

Each craftsman has his own style of nagashi, so it can be a meaning of

signature, like bar-code. Good nagashi is elegant, but difficult to make

by poor skill.

Such a work is not necessary to make a good polish. Sometimes it is just a trouble to study blade. So some craftsmen don't make that.